Copyright © 2018 Guangzhou Xilinear Machinery Co., Ltd.. | All Rights Reserved. 粤ICP备10213131号 Powered by: www.300.cn guangzhou.300.cn

Mob/WhatsApp:+86-13600046543

Tel:+86-020-32638488

Fax:020-32638426

Email:sales1@xilinear.cn;10086156@qq.com

Address: 132,Chuangqiang Road,Xintang Town,Zengcheng,Guangzhou City,China

CONTACT

Wechat Number

Summer beverage war is imminent, Guangzhou Xili helps to improve quality and efficiency!

In recent years, the domestic beverage market has performed well. According to Prospective Industry Research Institute, the total retail sales revenue of beverages in China reached 204 billion yuan from January to December 2018, an increase of 9% over the same period last year. At the same time, as the most important beverage packaging in the world, according to Euromonitor, the whole PET beverage industry will grow at an annual rate of 4.4% by 2019.

The high growth trend of PET bottled beverage market is obvious to all. The hot summer is coming. In order to seize the market share, in addition to introducing competitive new products and doing a good job in publicity and promotion, the most important thing is to improve the production process. Guangzhou Xili Machinery strives to build a leading technology, excellent performance and the most efficient packaging equipment production line. Its rotary blowing and filling rotary machine realizes innovative packaging technology from bottle blank to bottled liquid products by a single machine, which helps to reduce costs, improve quality and increase efficiency!

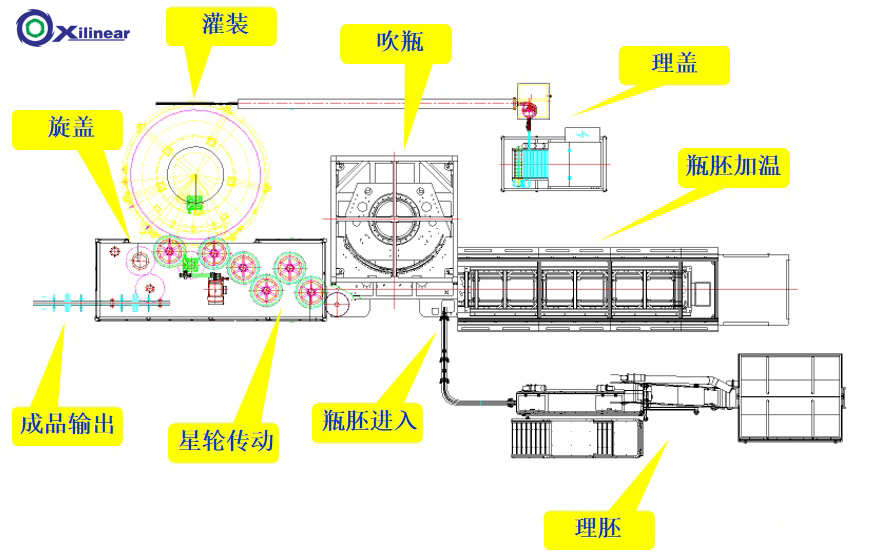

Rotary Blow-Irrigation Rotary Machine

Rotary blowing-filling-rotating machine represents the latest trend in the development of liquid packaging technology. It refers to the complete set of actions of blowing, filling and capping on a single equipment.

Rotary Blow-Fill Rotary Machine is an optimum combination of Rotary Bottle Blower and Filling Machine. This series is widely used in the production of various water and beverages.

Technical Advantage

(1) Mold closing system

The revolving clamping structure independently developed by our company has obtained patent certificate. The opening and closing die structure is realized by using the rotating shaft on the fixing frame and the clamping rod on the dynamic model, and by controlling the rotating angle position of the rotating shaft. Using the notch of the rotating shaft or the notch of the axle bump and the rod on the clamping rod to lock the mould directly reduces the power transfer of the transition, and replaces the linear motion with the rotating motion to make the work more stable and reliable.

(2) Heating mechanism system

The machine uses far-infrared lamp oven designed by Xili to radiate heating the bottle blank. The unique reflective sheet makes both sides of the bottle blank heated at the same time. The bottle blank moves forward and rotates at the same time, making the heating more uniform. At the same time, the cooling device is used to protect the bottle mouth from overheating and deformation, which improves the forming rate of the bottle qualitatively.

Technical characteristics

On the basis of "bottle blowing unit", "filling unit" and "cap revolving unit", the Xili Blow-Fill-Rotary Machine applies servo system to synchronize control through the comprehensive application of optics, mechanics, electricity, gas and other disciplines, so as to realize the integrated control and production of multiple units and equipment. The machine saves the equipment of empty bottle conveying and bottle washing in the conventional beverage filling production line, greatly saves the area occupied by the user's production line, reduces the use of bottle-flushing water and energy consumption of empty bottle conveying fan, reduces a large number of intermediate transmission links, and more reliably guarantees the cleanliness and hygiene of the whole equipment, and helps better. Help users to improve production efficiency, reduce investment costs, reduce energy consumption and equipment maintenance costs.

Main advantages

1. High production efficiency:

The maximum single-mode output is 24,000 bottles/models/hours.

2. Saving energy consumption:

The bottle embryo is heated at a distance of 38mm (when the supporting ring is less than 36mm), which saves 10-25% energy than the traditional heater.

The high pressure gas can be saved by 15-20% by selecting the gas distribution recovery system.

3. High degree of automation and intelligence:

The whole production process is completed independently by the machine. Friendly chart man-machine interface, the machine can be controlled according to people's wishes, at the same time, people can grasp the operation of the machine at any time through the data reflected by the man-machine interface. If a fault occurs, the maintenance personnel can repair it according to the type and cause of the fault shown in the man-machine interface.

4. Good and stable product quality:

- Stable infrared heating system, high precision closing system of blow mould, special designed and manufactured high-pressure blow valve, pneumatic components and electrical components using internationally renowned brands, as well as special designed stretch guides according to products, to ensure the accuracy of blow process and action; repetitive accuracy to ensure product quality and operation. The stability of quality is fully guaranteed.

5. High cleanliness, no intermediate pollution:Closed production area, excellent self-lubricating system, avoiding intermediate pollution (secondary pollution).

6. Low production cost:

Excellent process steps and design of process parameters greatly reduce electricity, gas and water consumption, and greatly reduce production costs.

7. Low noise:

- Advanced design means, excellent machine structure, professional assembly technology, ensure smooth operation of the machine, reduce noise.

- Equipped with high-pressure gas recovery system, using high-pressure gas recovery and decompression to blow bottles for pre-blowing and action gas, reducing air consumption by 15-25%.

technical parameter

Guangzhou Xili Machinery is one of the few first suppliers in China to master the two key technologies of PET bottle blowing machine and filling machine. It has rich experience in the whole line project. By innovating on-line forming technology, bottle blowing technology, filling technology and filling equipment, the rotary blowing-filling-rotating machine reduces the intermediate links such as transmission, empty bottle handling, stacking and storage processes, improves packaging sanitary conditions and reduces cross-contamination. Compared with the traditional single machine, the whole line efficiency is increased by 20% and the equipment is put into operation. Cost savings of 20%, area savings of 35%, energy consumption of the whole machine reduced by more than 30%, use cost and parts consumption reduced by nearly 50%, thus reducing the comprehensive production costs of beverage manufacturers.

Want to hit a new high in the main summer beverage market?