Copyright © 2018 Guangzhou Xilinear Machinery Co., Ltd.. | All Rights Reserved. 粤ICP备10213131号 Powered by: www.300.cn guangzhou.300.cn

Mob/WhatsApp:+86-13600046543

Tel:+86-020-32638488

Fax:020-32638426

Email:sales1@xilinear.cn;10086156@qq.com

Address: 132,Chuangqiang Road,Xintang Town,Zengcheng,Guangzhou City,China

CONTACT

Wechat Number

Tip: Do not know how to select oil filling machine? That's the right choice!

Edible oil is an indispensable part of people's daily life. It contains many essential nutrients for human body. As people pay more and more attention to daily diet, the quality and safety and hygiene standards of oils are becoming stricter and stricter, which is testing the technology and quality of oil filling machines.

It is well known that the filling of oil products requires high filling accuracy and hygiene, and because of the strong volatility of products, it is easy to adsorb the surface of parts and cause drip leakage. In order to solve these problems, Guangzhou Xili Machinery Co., Ltd. has gone through several years, striving for perfection, not only grasping the core filling technology, but also improving the appearance of the equipment to ensure accurate filling and sanitary operation.

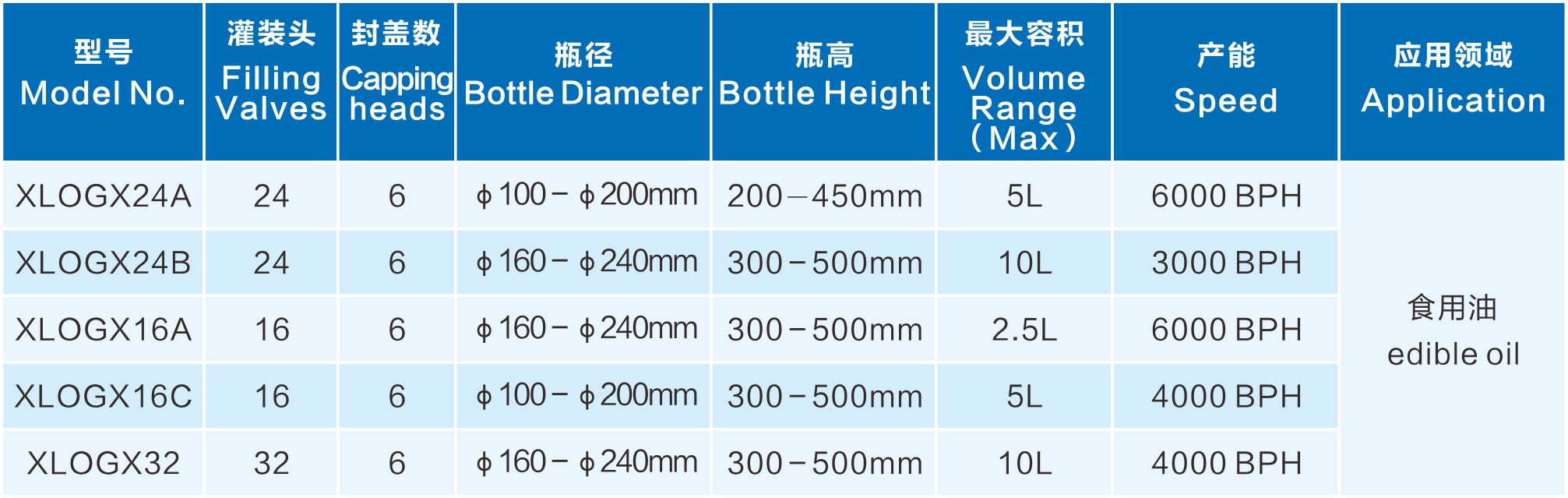

XLO series oil filling machine is a large bottle high-speed filling and capping machine independently developed by Guangzhou Xili with international advanced technology. This series of oil filling machine is composed of spiral drive, conveying chain, weighing filling machine, oil draining device, capping machine, conveying chain and removal conveying chain. It has high automation and intelligence, stable and reliable machine performance, high production efficiency, especially for oil filling drip leakage with unique solutions.

01 Technical Characteristics

1. Each filling head has a weighing and feedback system, which is controlled by pneumatic valve. It can set the filling quantity and adjust the filling quantity of each filling head.

2. Photoelectric sensors, proximity switches and so on are all advanced sensor elements, so that no bottle is filled.

3. The contact parts of materials are made of 316L stainless steel, which meets the requirements of GMP.

4. Double cylinder control to ensure filling accuracy of <2g;

5. High-efficiency inclined bucket centrifugal cover, cover wear is small, reverse cover rate is low.

02 system characteristics

1. The original imported uninterrupted torque rotary cap is adopted. The rotary cap has large torque, good stability and stability, and low noise. It is well used in other factories.

2. The filling valve patented by Guangzhou Xili Company has the advantages of fast filling speed, no drip leakage and splash, reducing the possibility of pipeline resistance loss and food pollution.

3. The HBM intelligent digital weighing module is adopted to automatically optimize the calibration of filling weight to ensure the continuous high-precision filling requirements, and to simply realize the conversion of different oil products and filling capacity, and the packing container with excessive weight does not need filling and has leak-proof function.

4. Realize remote monitoring and maintenance by means of network.

03 CIP Characteristics

1. The filling cylinder adopts conical design structure, which can clean faster and more thoroughly.

2. The cylinder is cleaned automatically and the oil product is switched by automatic circulation.

3. In CIP, the filling machine is cleaned uniformly at low speed, the filling valve has large caliber and no pipeline connection, the flow rate is fast, and the cleaning is more thorough and faster.

04 Production Functionality

1. Bottle feeding with a variety of detection and protection, there are inverted bottles and cap missing alarm shutdown, after troubleshooting can automatically start;

2. Bottle feeding and positioning stop can shield any filling valve or cap head for production.

3. The bottle-type related parts are replaced quickly without tools.

4. Configuration of removal conveyor chain, real-time monitoring of filling accuracy and cap quality, removal of non-conforming products in conveyor chain outside the export of equipment, positioning removal and sampling can be achieved.

At present, there are many kinds of edible oil filling machines on the market, and the quality is uneven. If we buy a filling machine with low quality, the filling effect will be greatly reduced, which will affect production. Do not know how to choose oil filling machine? It must be right to choose Guangzhou Xili.

Faced with the strong market demand, Guangzhou Xili Machinery Co., Ltd. actively carries out a series of technical research and development, starts to strengthen the automation level of oil filling equipment, faces the market's high requirements on filling efficiency, filling accuracy, filling stability, etc., continues to improve technology, constantly adjust and optimize, beats the edible oil filling machine. As a result, one of the hot-selling products of Xili in Guangzhou has been sold to many high-end grain and oil enterprises at home and abroad, which has won unanimous praise and remarkable advantages in the industry.