Copyright © 2018 Guangzhou Xilinear Machinery Co., Ltd.. | All Rights Reserved. 粤ICP备10213131号 Powered by: www.300.cn guangzhou.300.cn

Mob/WhatsApp:+86-13600046543

Tel:+86-020-32638488

Fax:020-32638426

Email:sales1@xilinear.cn;10086156@qq.com

Address: 132,Chuangqiang Road,Xintang Town,Zengcheng,Guangzhou City,China

CONTACT

Wechat Number

Disclosure how Guangzhou Xili builds high-quality disposable PET barrel packaging production equipment

With the continuous improvement of people's living standards, people pay more and more attention to health, and spend a lot of money on daily food, clothing, housing and transportation, especially drinking water, which is almost indispensable every day. In this case, the quality of barreled water will directly affect the corporate brand image, product sales and market share.

Every day, recycling barrels come from all sides. Pollution is unavoidable, such as scale, oil, soil, chewing gum and even odor. The operating efficiency, sales radius, transportation cost and labor cost involved will be greatly reduced, which is an invariable indication that recycled packaging barrels of water will never return.

In view of the above, disposable packaging obviously has more advantages and meets the economic benefits.

Guangzhou Xili Machinery adheres to excellence, strictly enforces every detail, integrates "bottle blowing technology" and "filling technology", realizes automation of the whole line, greatly improves production efficiency, and strives to build high-quality disposable PET barrel packaging production equipment.

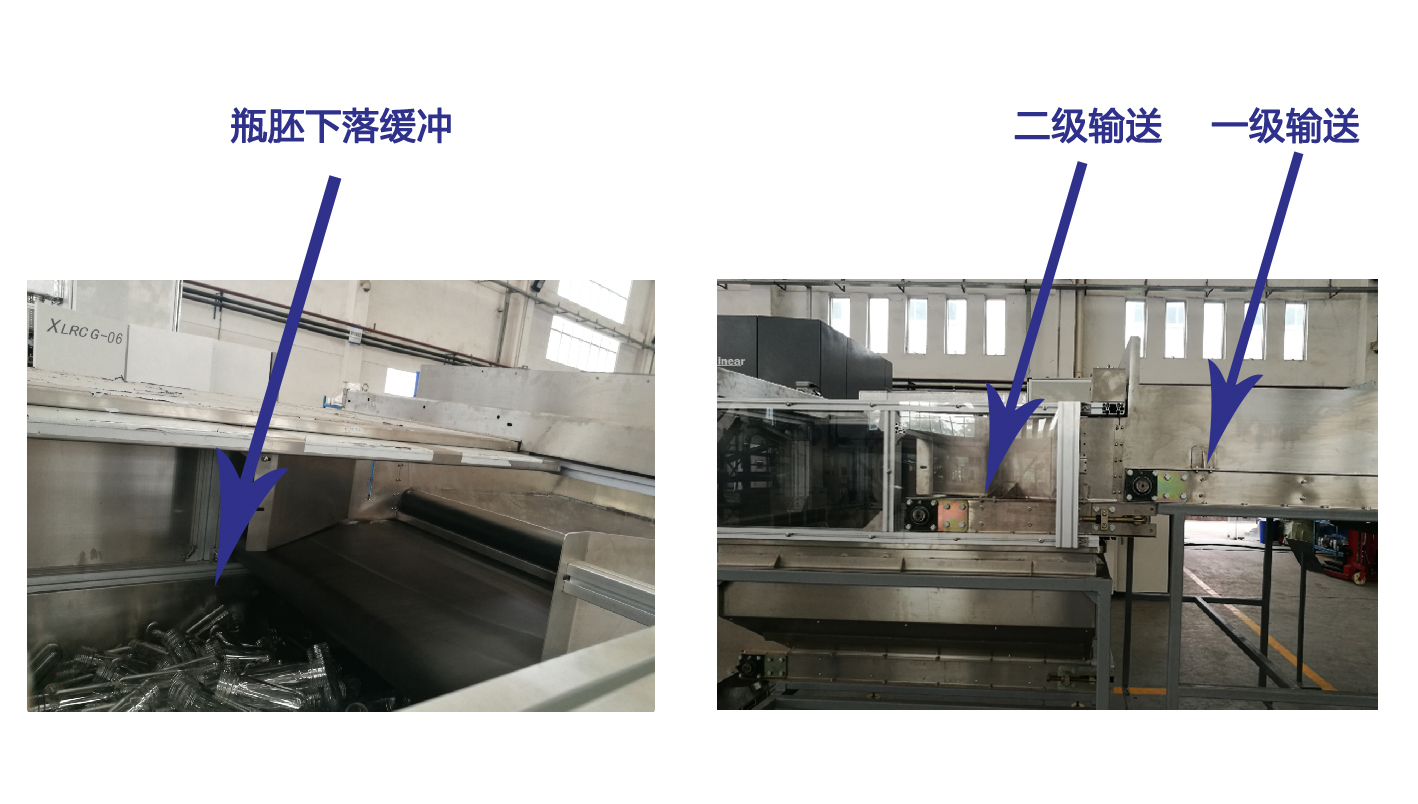

I. Rotary Bottle Blowing System

1. Bottle embryo protection to avoid damage to appearance caused by collision and extrusion.

2. The bottle embryo is clean. Sili has developed and applied for a patent. The bottle embryo is driven by a motor with a runner partition structure. It rotates 360 degrees. It is equipped with a high-pressure nozzle and a negative pressure removal system to clean the dust, fibers and other adhesives in the bottle embryo and larger particle contaminants. And can easily carry out visual detection, detection of bottle mouth, bottle bottom detection and elimination.

Runner Dust Removal Device

Visual Detection

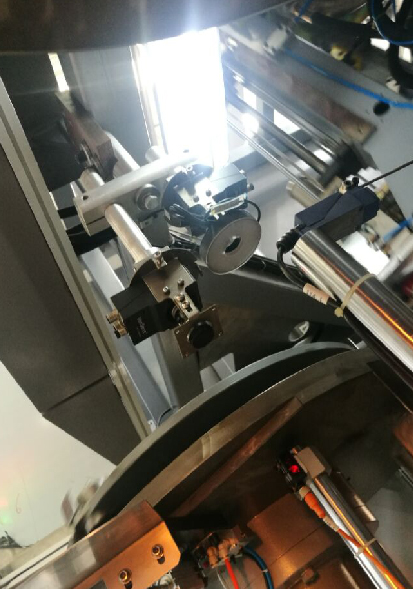

3. Bottle shape is more uniform, using Schneider servo stretching system, greatly reducing impact, low vibration and low noise. The operation energy consumption is low, which is more than 20% energy saving than the pneumatic stretching system.

4. Temperature control of bottle embryo, using high-intensity infrared penetrating lamp tube, ceramic reflector and PID constant temperature system, temperature control of bottle embryo.

5. Bottle blowing system

(1) Rotary Bottle Blowing, Capacity (>3000BPH)

(2) Proportional adjustment of pre-blower, high-pressure air sterile filtration system, filtering accuracy of 0.01um

(3) Additional blow action is more uniform in bottle forming.

(4) Automatic elimination of pressure detection

_High strength die steel with service life of 6 million times

Saichi 6 Valve Set Pneumatic Control, Good Control of Blowing to Improve Bottle Wall Thickness

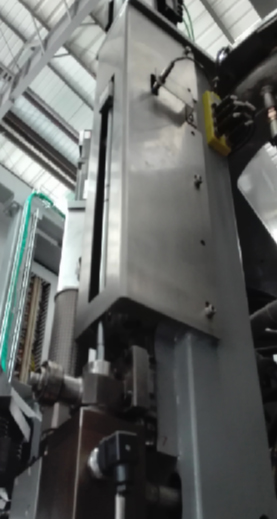

2. Filling and capping system

1. The filling system has the function of CIP cleaning to ensure the quality of products. Each canned tank has an automatic CIP cylinder, which needs no human intervention when CIP is needed and has a high degree of automation.

2. The products of COP system are clean, and the parts contacted with the bottle mouth are equipped with exterior sterilizing and cleaning devices to further ensure the quality and eliminate the potential safety hazards of the products. At the same time, the sprinkler adopts laser cutting technology.

3. Automatic capping system

(1) Back cover detection, automatic kick cover

(2) Professional laser cutting technology

(3) Installation of double-position detection device with missing cover and reverse cover, and automatic shutdown of missing cover or reverse cover equipment was found.

(4) Independent Schneider servo motor drives the cap spinning with adjustable speed.

The spindle control cam of the cap is made of hard steel to prevent deformation.

Watch the video to witness the high quality of Xili Guangzhou!

↓↓↓

Advanced technology, professional staff, strict quality inspection and spare parts checks and perfect after-service, all these efforts step by step let Guangzhou Xili build a high-quality PET packaging equipment production line, so that customers trust, recognition and approval!