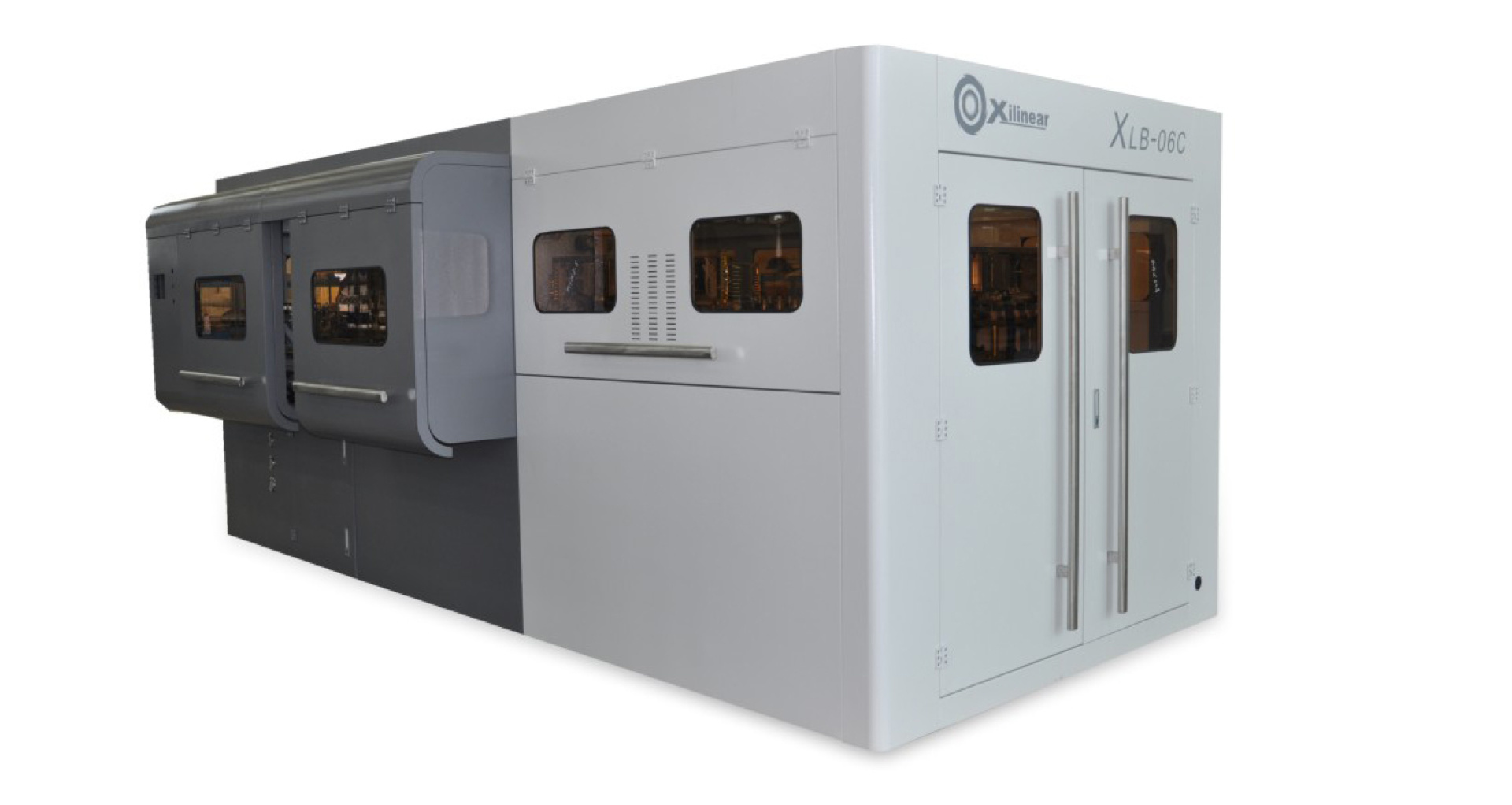

Standard Linear Machine

Standard series is designed independently by Xili company, and combined with market and customer needs to research and develop small and medium linear blow molding machine.

Category: Linear Machines

Keyword: Standard Linear Machine

Products

Standard series is designed independently by Xili company, and combined with market and customer needs to research and develop small and medium linear blow molding machine. This machine combined with the main blowing unit, heating oven, auto preform feeder and servo motor control system, suitable for blowing various bottle-shaped, with the characteristics of simple operation, low failure rate, high stability, and high cost effective.

The main structure and principle of the machine:

A,clamping part by positioning rack balance position, after the former three templates, hyperbolic arm linkage, clamping cylinder, driven by electromagnetic direction valve drive cylinder connecting rod crank arm to realize the process.The reasonable structure design, the work is smooth operation, clamping force.

B, stretch blow by stretching the electromagnetic valve, high pressure valve, body sealing cylinder, the sealing seat, blowing gas reservoir.Work through the direction control valve drive stretching cylinder piston, drive the tensile rod and seal cylinder upward on the top of the bottle preform mould clamping, sealing cylinder seal bottle mouth, stretching rod to the already heated elastic shaped bottle preform longitudinal extension, and stored in the gas reservoir of the gas by high-pressure blow after sealing the cylinder for bottom blowing bottle preform, high-pressure blow molding.

C, heating roller chain plate by stepping cylinder a workstation, the photoelectric switch to detect positioning, again by blow molding mechanism make the product, the step cylinder in promoting a station location, the cycle of continuous production.

D, rotation chain through the motor driving continuous work, to make the bottle preform drying tunnel uniform heat quickly.

E, bottle preform by feeder system in transmission, the bottle preform by the manipulator is installed on the bottle base, enter the path

F, there were two relatively independent set of far-infrared heating tube of the oven, oven in each group of each far infrared tubes according to different bottle preform in longitudinal do before and after the adjustment.

Features of blow molding machines for pet preform blowing:

1.Operation is simple and easy

2.Compacted mechanical structure

3.No contamination

4.Stable heating systems

5.The passing rate of blow bottle is over 99%.

6.By rotary and soft preform inlet system, the speed of prefom feeding is ensured meanwhile, the preform neck is well protected.

7.After the bottle blowing, high-pressure air can be recycled and used again for the pre-blowing and machine physical movement.

Equipment Type and Technical Parameters:

Guangzhou Xili Standard Linear Machine Series includes XLB-04CE, XLB-04CL, XLB-05CE, XLB-06C, XLB-06CL, XLB-08C and other equipment.

|

XLB-04CE |

Project |

Technical data |

|

Bottle volume range(Max) |

2.5 |

|

|

Max. bottle diameter(mm) |

Φ130 |

|

|

Bottle neck diameter(mm) |

Φ20~ Φ38 |

|

|

Bottle height range |

<320 |

|

|

BPH/output |

3,000~3,500 |

|

|

Blowing cavity |

4 |

|

|

Blower size(L*W*H) |

5280 ×2360 × 2350 mm |

|

XLB-04CL |

Project |

Technical data |

|

Bottle volume range(Max) |

1.5 |

|

|

Max. bottle diameter(mm) |

Φ90 |

|

|

Bottle neck diameter(mm) |

Φ20 ~ Φ38 |

|

|

Bottle height range |

<320 |

|

|

BPH/output |

3,200~4,000 |

|

|

Blowing cavity |

4 |

|

|

Blower size(L*W*H) |

4942 × 2254 × 2170mm |

|

XLB-05CE |

Project |

Technical data |

|

Bottle volume range(Max) |

2 |

|

|

Max. bottle diameter(mm) |

Φ110 |

|

|

Bottle neck diameter(mm) |

Φ20 ~ Φ38 |

|

|

Bottle height range |

<320 |

|

|

BPH/output |

4,000~4,300 |

|

|

Blowing cavity |

5 |

|

|

Blower size(L*W*H) |

5280 × 2360 ×2350mm |

|

XLB-06C |

Project |

Technical data |

|

Bottle volume range(Max) |

0.75 |

|

|

Max. bottle diameter(mm) |

Φ70 |

|

|

Bottle neck diameter(mm) |

Φ20 ~ Φ38 |

|

|

Bottle height range |

<240 |

|

|

BPH/output |

5,500~6,000 |

|

|

Blowing cavity |

6 |

|

|

Blower size(L*W*H) |

4850 × 2150 ×2200mm |

|

XLB-06CL |

Project |

Technical data |

|

Bottle volume range(Max) |

1.5 |

|

|

Max. bottle diameter(mm) |

Φ90 |

|

|

Bottle neck diameter(mm) |

Φ20 ~ Φ38 |

|

|

Bottle height range |

<320 |

|

|

BPH/output |

5,500~6,000 |

|

|

Blowing cavity |

6 |

|

|

Blower size(L*W*H) |

5350×2090× 2220 mm |

|

XLB-08C |

Project |

Technical data |

|

Bottle volume range(Max) |

0.75 |

|

|

Max. bottle diameter(mm) |

Φ70 |

|

|

Bottle neck diameter(mm) |

Φ20 ~ Φ38 |

|

|

Bottle height range |

<240 |

|

|

BPH/output |

7,500-8,000 |

|

|

Blowing cavity |

8 |

|

|

Blower size(L*W*H) |

4950 ×2360 ×2100mm |

Product Consulting