Main feature of rotary PET bottle blowing molding machine

Release time:

2024-01-08 15:54

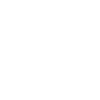

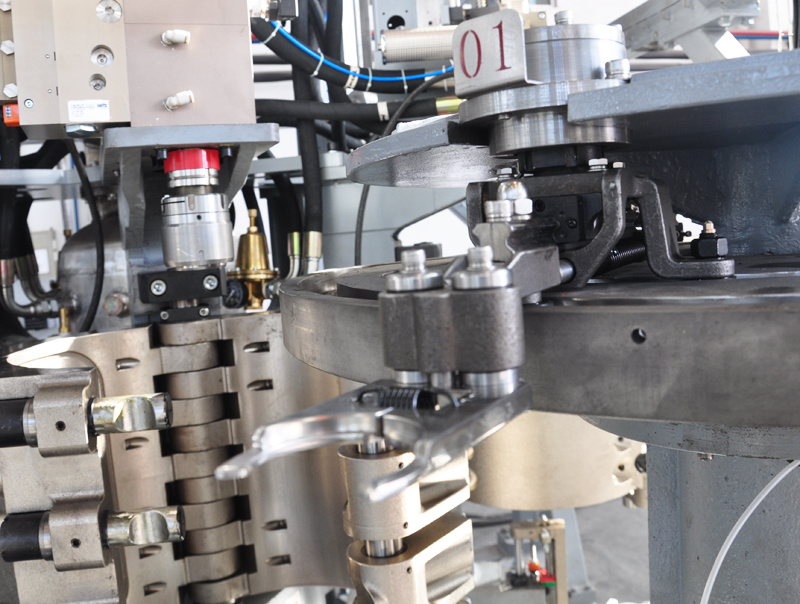

The XLRCL-10 fully automatic rotary PET bottle blowing molding machine is designed and built by our advanced technology, the machine produce the PET bottle with high pressure compressed air. The whole operation process is of self control and is free of manual operation.

The machine integrate with intelligence, automation, stability, high output, economy and it is free of pollution.

Rotary PET bottle blowing molding machine is widely used in food,beverages,,cosmetics,pharmaceutical container production.

Mould: Xilinear have adopted the latest CAD/CAE/CAM system to our mould design, such as UG, Pro-E that ensures the project efficiency. Also, we have advanced processing equipment. Your product will be through effective project management that will reduce the costs and let your products show on the market in the shortest time.

Preform feeding: The preforms are unloaded into the preform hopper and are then transferred to unscrambler by a preform elevator. The unscrambler conveys preforms to a feed rail, at the end of rail the preforms are captured by in-feeding star-wheel. Then preforms are sent to the heating module.

Horizontal preform heating: The preforms start moving along the heating module. During the heating process, the preforms constantly turn around themselves, so as to ensure an excellent and symmetrical heat distribution. Each oven module and each lamp can be adjusted with regards to position and power, thus assuring the maximum process setting flexibility. At the heating module outlet, a sensor detects the preform temperature and compares it with the temperature setting point; if the two values do not correspond; it increases or decreases the heating module lamps power.

Preforms stretch blow-moulding: After leaving the heating oven, preforms are transferred by mechanically synchronized gripper fixed on the transfer wheel to the cam-controlled blow wheel. In blowing stations, there are two phases of stretch-blowing process:

---stretching and pre-blowing, which occur simultaneously through the descent of the stretching rod and the supply of low-pressure compressed air;

---final blowing with high-pressure compressed air, through which the bottles take their final shape.

PET,bottle,blowing,molding,machine

Previous Page

MESSAGE

CONTACT

Fax: 020-32638426

Headquarters Address: 132 Chuangqiang Road, Xintang Town,Zengcheng,Guangzhou City,China

Wechat Number

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Copyright©2018 Guangzhou Xili Machinery Co.,Ltd. All Rights Reserved.

SEO city substation Powered by: www.300.cn