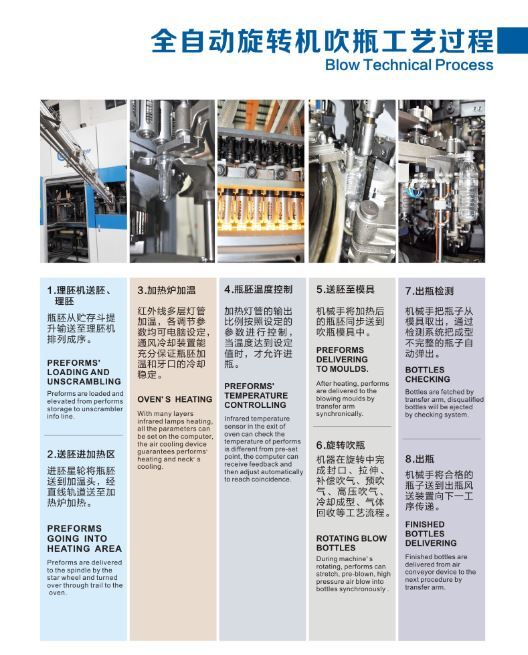

Automatic Rotary Machine Blowing Process

Release time:

2024-01-08 15:54

Rotary blow molding machine practice proved it works for more energy saving,more simple operation and more easy bottle changes parts adjustment.Also Rotary blow molding machine has low noise and durable life and other special features.It performs in high automatic,reliable,high effciency and safety to improve the production cost.

Blow technical process:

1、Preforms' loading and unscrambling

Preforms are loaded and elevated from performs storage to unscrambler info line.

2、Preforms’ going into heating area

Preforms are delivered to the spindle by the star wheel and turned over through trail to the oven.

3、Over's heating

With many layers infrared lamps heating.all the parameters can be set on the computer,the air cooling device guarantees performs' heating and neck‘s cooling.

4、Preforms’temperature controlling

Infrared temperature sensor in the exit of oven can check the temperature of performs is different from pre-set point,the computer can receive feedback and then adjust automatically to reach coincidence.

5、Preforms delivering to moulds

After heating,performs are delivered to the blowing moulds by transfer arm synchronically.

6、Rotating blow bottles

During machine's rotating,performs can stretch,pre-blown,high pressure air blow into bottles synchronously.

7、Bottles checking

Bottles are fetched by transfer arm,disqualified bottles will be ejected by checking system.

8、Finished bottles delivering

Finished bottles are delivered from air conveyor device to the next procedure by transfer arm.

Xilinear is one of the first factories in China to produce rotary blow molding machine .

Rotary,blow,molding,machine

MESSAGE

CONTACT

Fax: 020-32638426

Headquarters Address: 132 Chuangqiang Road, Xintang Town,Zengcheng,Guangzhou City,China

Wechat Number

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Copyright©2018 Guangzhou Xili Machinery Co.,Ltd. All Rights Reserved.

SEO city substation Powered by: www.300.cn